Inkqubo ye-laminating kunye ne-glazing process zombini zezodidi lwe-post-printing surface finishing processing yezinto eziprintiweyo. Imisebenzi yale mibini iyafana kakhulu, kwaye zombini inokudlala indima ethile ekuhombiseni nasekukhuseleni umphezulu wento eprintiweyo, kodwa kukho umahluko phakathi kwezi zimbini:

Ukugqitywa komphezulu

Ukugqitywa komphezulu kukwenza inkqubo efanelekileyo kumphezulu womcimbi oshicilelweyo ukuphucula ukunyanzeliswa kokukhanya, ukuxhathisa kwamanzi, ukuxhathisa ubushushu, ukumelana nokusonga, ukunyanzeliswa kokugqoka kunye nokuchasana kweekhemikhali kumcimbi oshicilelweyo; ukwandisa iglosi kunye nengqiqo yobugcisa bento eprintiweyo; kunye nokukhusela umba oshicilelweyo. Kunye nomsebenzi wokuhombisa umba oshicilelweyo nokunyusa ixabiso lezinto ezishicilelweyo. Iindlela eziqhelekileyo zokulungiswa komphezulu wezinto ezishicilelweyo ziquka ukukhenkceza, ukunyibilika, ukupholisa, ukusika, ukusika okanye okunye ukusetyenzwa.

01 intsingiselo

Laminationyinkqubo yokuprinta emva kokuba ifilimu yeplastiki ehlanganiswe nge-adhesive ihlanganiswe phezu kwendawo eprintiweyo. Emva kokufudumeza kunye noxinzelelo lonyango, into eprintiweyo kunye nefilimu yeplastiki ihlanganiswe ngokusondeleyo ukuze ibe yimveliso edibeneyo yephepha-plastiki. Inkqubo ye-laminating iyingxenye yenkqubo ye-paper-plastic composite kwi-composite process kwaye i-composite eyomileyo.

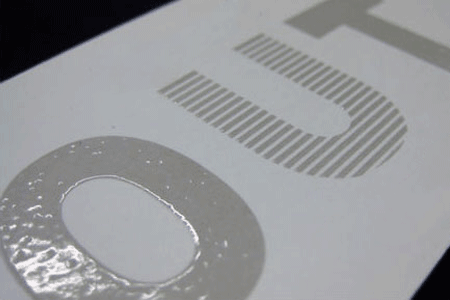

I-glazing yinkqubo apho umgca wepeyinti engabonakaliyo engenambala ifakwe (okanye itshizwe okanye iprintwe) kumphezulu wento eprintiweyo. Emva kokulinganisa kunye nokomisa (i-calendering), umaleko oqaqambileyo obhityileyo kwaye ocacileyo wenziwa kumphezulu wento eprintiweyo. Inkqubo yokugcoba (eyaziwa ngokuba yinkqubo yokusetyenziswa kwe-varnish (kubandakanya i-resin yokwenza ifilimu, i-solvent kunye ne-additives) kumphezulu wezinto eziprintiweyo zokulinganisa kunye nokomisa.

02 Umsebenzi kunye nentsingiselo

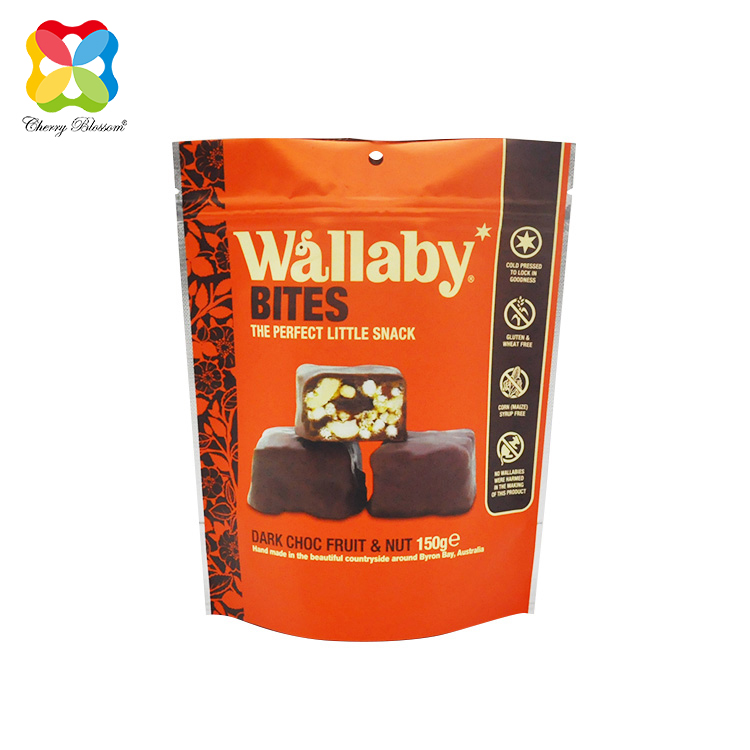

Emva kokuba umphezulu wento eprintiweyo igutyungelwe ngumaleko wefilimu yeplastiki (i-coating) okanye ifakwe ngepeyinti yepeyinti ekhazimulayo (i-glazing), into eprintiweyo inokwenziwa ukuba ibe nemisebenzi yokumelana nokukhuhlana, umswakama-ubumanzi, ukungabikho kwamanzi kunye i-anti-fouling, njl., engakhuseli kuphela into eprintiweyo, kodwa ikhusela umba oshicilelweyo. Ukwandisa ubomi bayo benkonzo, ikwaphucula ukuqaqamba komphezulu wento eprintiweyo, iphucula ixabiso layo lokuhombisa, yenza imizobo eprintiweyo kunye nombhalo uqaqambe ngombala, kwaye ibe nempembelelo ebonakalayo eyomeleleyo, ngaloo ndlela iphucula umgangatho wemveliso kwaye yandise imveliso. ixabiso elongeziweyo. Ngokomzekelo, i-cover cover lamination, i-surface glazing yeebhokisi zokupakisha ze-cosmetic, njl.

Ke ngoko, i-laminating kunye ne-glazing yenye yetekhnoloji ephambili yokusetyenzwa kwe-post-printing surface finishing into eprintiweyo. Abakwazi nje "ukukhanyisa" umphezulu wento eprintiweyo kwaye batsale ingqalelo yabathengi, kodwa bakhusele umba oshicilelweyo kunye nokuphucula ukusebenza kwayo. Ngoku zisetyenziswa ngokubanzi. Ifanelekile ukuhombisa umphezulu weencwadi, ii-periodicals, ii-albhamu zemifanekiso, amaxwebhu ahlukeneyo, iincwadana zentengiso kunye nokuhombisa umphezulu wemveliso yokupakisha iphepha.

03 Inkqubo yahlukile

Inkqubo yokugquma ifilimu Inkqubo yokugquma ifilimu inokwahlulwa ibe yitekhnoloji yefilimu yokugquma ngoko nangoko kunye neteknoloji yokugquma ifilimu yangaphambili ngokwezinto ezahlukeneyo kunye nezixhobo ezisetyenzisiweyo.

1) Iifilimu yokwaleka qhubekeka kuqala isebenzisa isixhobo sokugquma i-roller ukugqoka ngokulinganayo i-adhesive kumphezulu wefilimu yeplastiki. Emva kokudlula kwisixhobo sokumisa, i-solvent kwi-adhesive i-evaporated, kwaye ke into eprintiweyo itsalwa kwisixhobo sokucoca esishushu. Kumatshini, iifilimu yeplastikikwaye izinto eziprintiweyo zicinezelwe kunye ukuze kugqitywe i-lamination kunye nokubuyisela umva, kwaye emva koko zigcinwe ukubunjwa kunye nokunqunyulwa. Le ndlela ngoku isetyenziswa ngokuqhelekileyo eTshayina. Ukususela kumbono wezinto zokubambelela ezisetyenziswe kwifilimu yokugqoka, inokwahlulwa ibe yifilimu edibeneyo esekelwe kwi-solvent kunye nefilimu yokubambelela emanzini.

2) Ifilimu yokugubungela kwangaphambili Inkqubo yefilimu yangaphambi kokugquma yeyabavelisi abaziingcali ukuba bafake izinto zokuncamathelisa kwangaphambili ngokobungakanani nangokulinganayo kwiifilimu zeplastiki, zome, zibuyisele umva, kwaye zizipakishe kwiimveliso ezithengiswayo, emva koko iinkampani ezilungisayo zisebenzisa i-adhesive-free inheating kuzo. Ukucofa okutshisayo kwenziwa kwisixhobo sokulayita isixhobo sokugqiba inkqubo yokucoca into eprintiweyo. Inkqubo yefilimu yangaphambili ilula kakhulu inkqubo yokugqoka ngenxa yokuba izixhobo zokugquma azifuni i-adhesive heat and drying system, kwaye ilula kakhulu ukusebenza. Ngexesha elifanayo, akukho ukuguquguquka kwe-solvent kunye nokungcola kwendalo, okuphucula indawo yokusebenza; okubaluleke kakhulu, oko Ukwenzeka kokusilela komgangatho wokugquma njengamaqamza kunye ne-delamination kuphetshwe ngokupheleleyo. Ukungafihli kweemveliso ezigqunyiweyo kuphezulu kakhulu. Xa kuthelekiswa nenkqubo yokwambathisa eqhelekileyo, inamathuba abanzi okusebenza.

1) I-solvent-based glazing I-solvent-based glazing ibhekiselele kwinkqubo yokukhenkceza esebenzisa i-benzene, i-esters kunye ne-alcohol njengezinyibilikisi kunye nentlaka ye-thermoplastic njenge-filimi-forming resin. Ngethuba lenkqubo ye-glazing, i-solvent iyaphuphuma kwaye i-resin i-polymerizes okanye i-Cross-linking reaction reaction yenza ifilimu. Ibonakaliswe ngotyalo-mali oluncinci lwezixhobo kunye neendleko eziphantsi, kodwa i-solvent volatilization kunye ne-residu kumbandela oshicilelweyo kuya kubangela ukungcoliseka kwendalo kwaye kube yingozi kumzimba womntu.

2) Ukukhenkceza okusekelwe emanzini I-glazing esekelwe kumanzi yindlela yokukhenkceza esebenzisa i-resin e-soluble yamanzi okanye iintlobo ezahlukeneyo ze-resin ezichithwa ngamanzi njengezinto zokwenza ifilimu. Ipeyinti ecwebezelayo esekwe emanzini isebenzisa amanzi njengesinyibilikisi, kwaye akukho nto iguquguqukayo ye-organic solvent ngexesha lokwaleka kunye nokomisa. Isici kukuba inkqubo ye-glazing ayinalo ivumba elicaphukisayo, akukho ngcoliseko kwindalo, kwaye ayinabungozi kumzimba womntu. Isetyenziswa kakhulu kwipakethe yecuba, iyeza, ukutya, izinto zokuthambisa kunye nezinye izinto.

3) Ukukhanya kweUV Ukukhenkceza kweUV yimitha yeultraviolet eyomileyo. Isebenzisa imisebe ye-ultraviolet ukukhupha i-oyile ye-glazing ukuze iqalise ngokukhawuleza i-photochemical reaction ye-glazing oil ukuze yenze i-coating eqaqambileyo kunye nesakhiwo sekhemikhali yenethiwekhi phezu kwendawo eprintiweyo. Inkqubo yokucoca i-glazing iyafana nenkqubo yokomisa i-inki ye-UV. Ibonakaliswa yi-gloss elungileyo, ukumelana nobushushu obunamandla kunye nokumelana nokugqoka, ukomisa ngokukhawuleza, ukhuseleko kunye nokukhuselwa kwendalo. Inemibono ebanzi yophuhliso lwemarike. Njenge-glazing yamanzi, isetyenziswa kakhulu kwiyeza, ukutya, njl njl. Ukupakishwa kwemveliso kwintsimi.

Ixesha lokuposa: Dec-13-2023