"Ngaba uyakuqonda ngokwenene ukupakisha ukuprinta?

Impendulo ayiyona nto ibalulekileyo, imveliso esebenzayo lixabiso leli nqaku. Ukusuka kuyilo ukuya ekuphunyezweni kweemveliso zokupakisha, kudla ngokuba lula ukungahoyi iinkcukacha phambi kokushicilela. Ngokukodwa abaqulunqi bokupakisha, abanokuqonda okungaphezulu nje kokuprinta, bahlala besenza "njengabangaphandle". Ukomeleza unxibelelwano phakathi kwabaqulunqi bokupakisha kunye neefektri zokushicilela, namhlanje ndiza kukukhumbuza ezo nkcukacha ekulula ukuzihoya phambi kokushicilela!

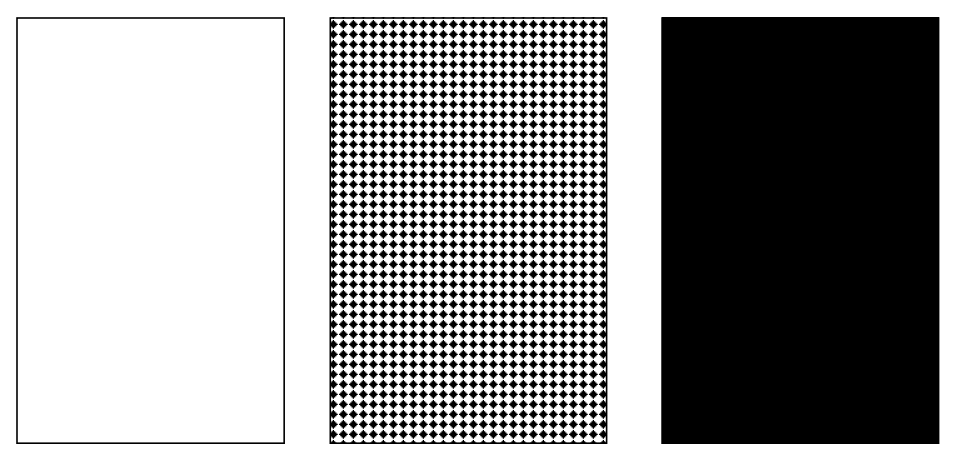

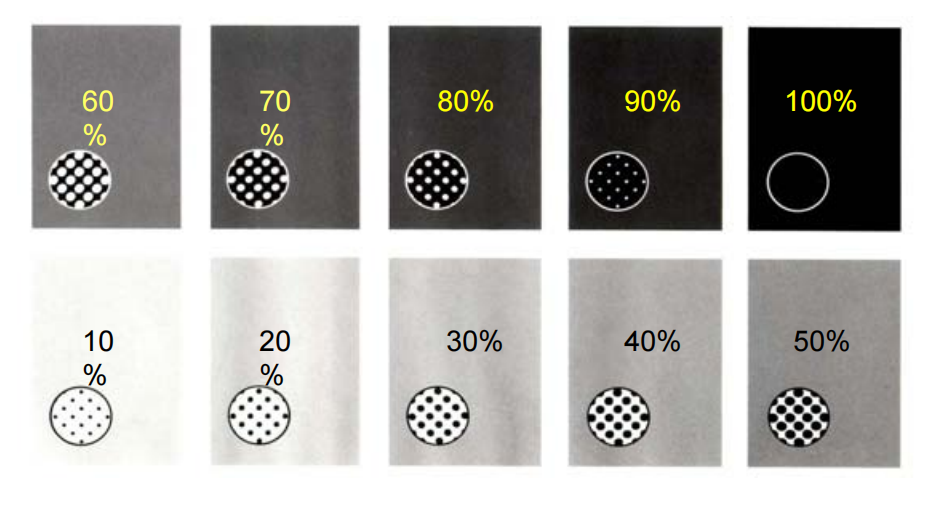

Amachaphaza okushicilela

Kutheni sifuna amachaphaza?

Amachaphaza ngoku yeyona ndlela yongayo nesebenzayo yokuvakalisa umgangatho phakathi kwabamnyama nabamhlophe. Kungenjalo, amakhulu ee-inki ezahlukeneyo ezingwevu kufuneka zilungiswe kwangaphambili ukuze ziprintwe. Iindleko, ixesha kunye neteknoloji zonke iingxaki. Ushicilelo lusengu-zero kunye nengqikelelo enye.

Ubuninzi bokuhanjiswa kwamachaphaza buhlukile, ngoko ke imibala eprintiweyo iya kwahluka ngokwendalo.

Ukukhanya kwangaphambili

Ukuhlolwa kwe-preflight ukuqinisekisa ukuchaneka kwefayile yenkcazelo yephepha; umqhubekekisi wetikiti lomsebenzi wamkela ifayile yenkcazelo yephepha eya kungena kwinkqubo, emva koko enze imisebenzi yokuqalisa kwitikiti lomsebenzi; inyathelo elilandelayo kukuseta isikhewu sokuzaliswa, ukutshintshwa komfanekiso, ukubekwa, ukwahlulwa kombala, ulawulo lombala kunye neeparamitha zemveliso, kwaye iziphumo zibonakaliswa kwitikiti lomsebenzi.

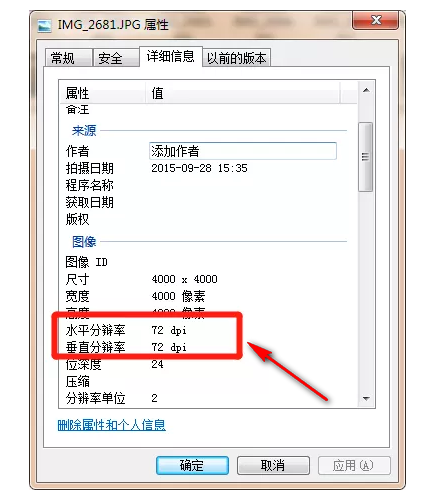

Isisombululo seDPI

Xa kuziwa kwisisombululo, asinakuzibamba kodwa sikhankanya "imizobo yevektha" kunye "ne-bitmaps".

Imizobo yeVektha:Imizobo ayigqwethwanga xa yandiswa okanye icuthwa

Imephu yeBitmap:I-DPI-inani leepixels eziqulethwe kwi-intshi nganye

Ngokuqhelekileyo, imizobo eboniswe kwisikrini sethu yi-72dpi okanye i-96dpi, kunye nemifanekiso kwiifayile eziprintiweyo kufuneka zihlangabezane ne-300dpi +, kwaye imizobo kufuneka ifakwe kwi-software ye-Ai.

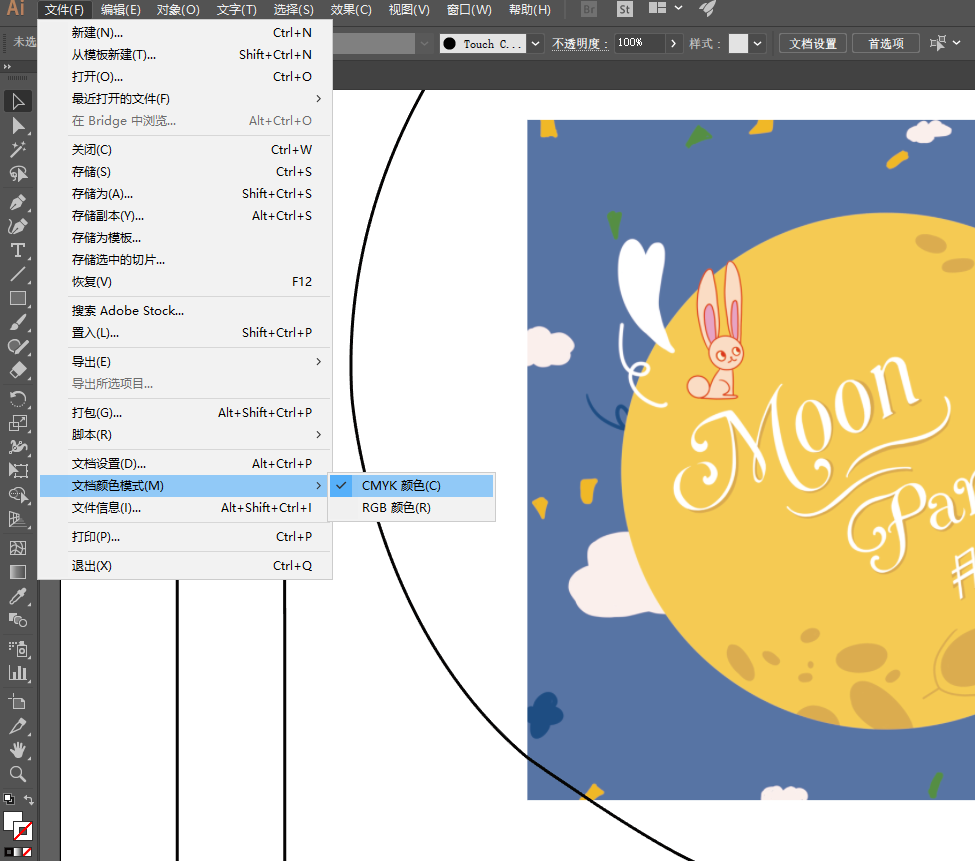

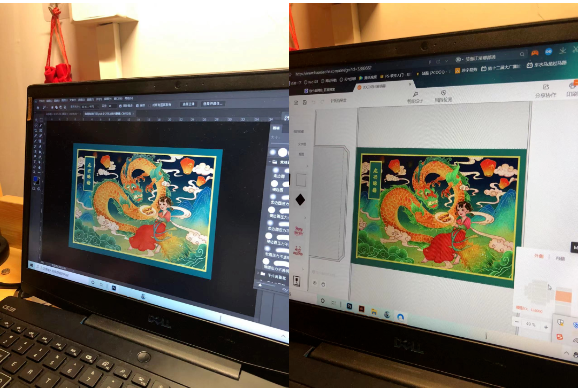

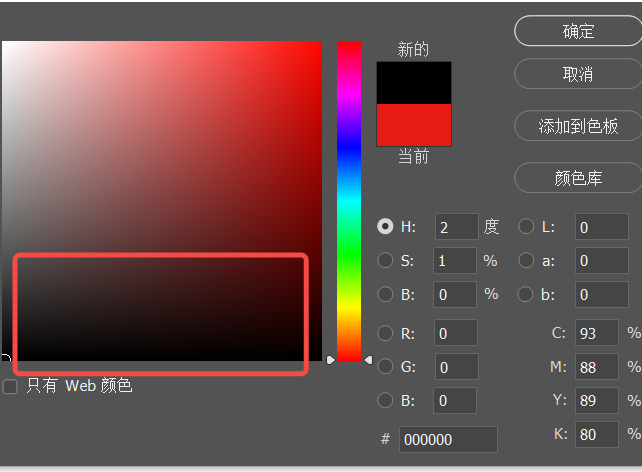

Imo Yombala

Ifayile yoshicilelo kufuneka ibe kwimo ye CMYK. Ukuba ayiguqulelwanga kwi-CMYK, kunokwenzeka ukuba umphumo woyilo awuyi kushicilelwa, nto leyo esihlala siyibiza ngokuba yingxaki yokwahlukana kombala. Imibala ye-CMYK ihlala imnyama kunemibala ye-RGB.

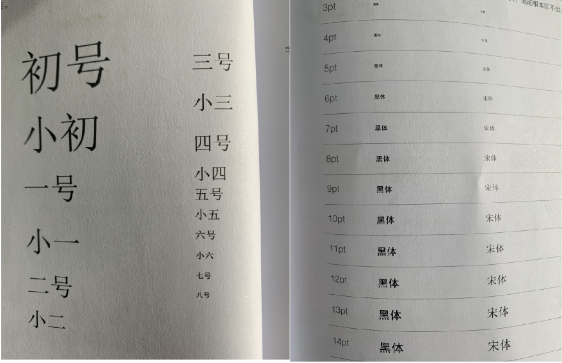

Ubungakanani befonti kunye nemigca

Zimbini iindlela zokuchaza ubungakanani befonti, ezizezi, inkqubo yamanani kunye nenkqubo yeengongoma.

Kwinkqubo yamanani, ifonti enamanqaku asibhozo yeyona incinane.

Kwinkqubo yamanqaku, i-1 pound ≈ 0.35mm, kunye ne-6pt yisayizi yefonti encinci enokufundwa ngokuqhelekileyo. Ke ngoko, obona bungakanani befonti buncinci boshicilelo lusetelwe gabalala ukuya ku-6pt

(Obona buncinane besayizi yefonti yeUkupakishwa kweHongzeingamiselwa ku 4pt)

Umgca wokushicilela, ubuncinci be-0.1pt.

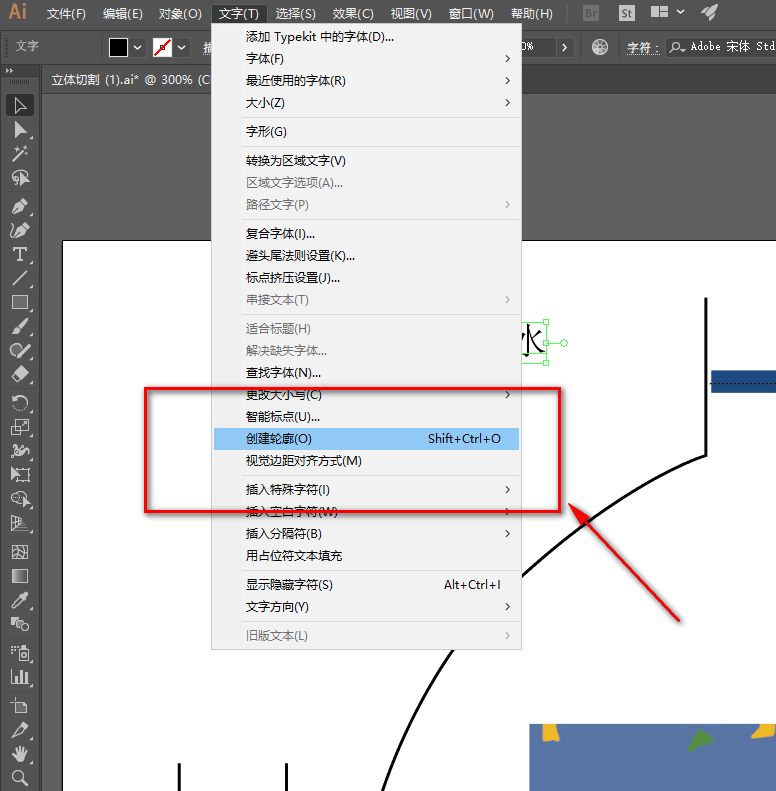

Uguqulelo lwefonti/ungqamaniso

Ngokubanzi, zimbalwa izindlu zokushicilela ezinokufaka zonke iifonti zesiTshayina nesiNgesi. Ukuba ikhompyutha yendlu yoshicilelo ayinayo lo mgca, ifonti ayiyi kuboniswa ngokuqhelekileyo. Ke ngoko, ifonti kufuneka iguqulwe ibe yigophe kwifayile yoyilo lokupakisha.

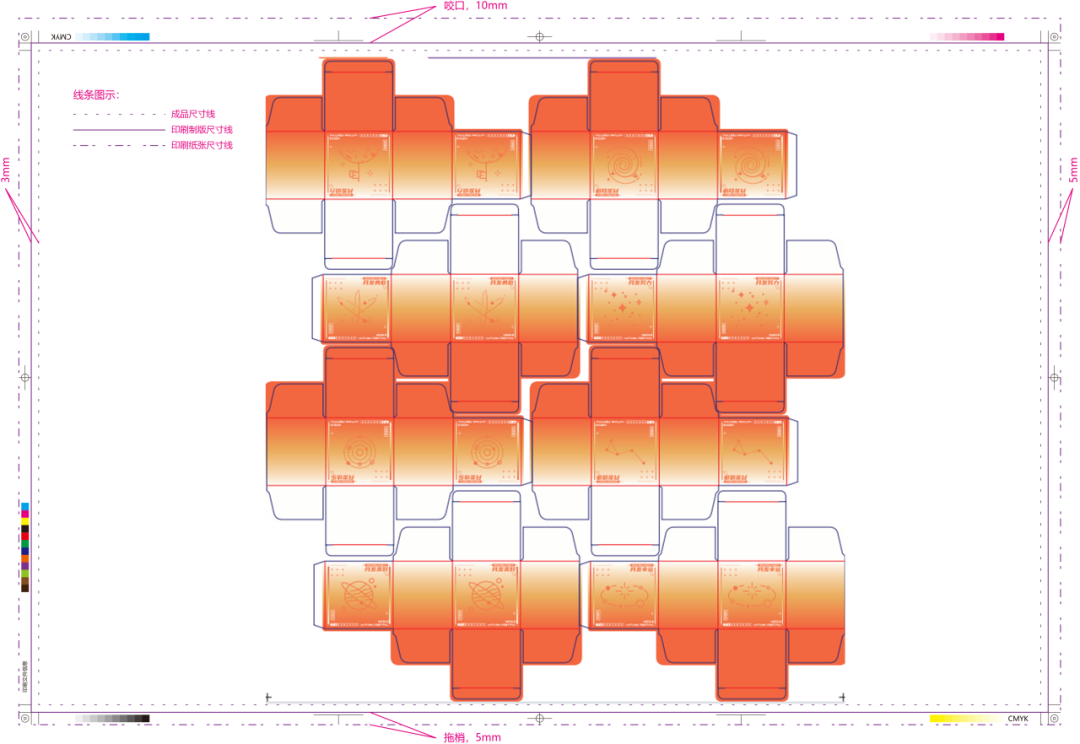

Ukopha

Ukopha kubhekisela kwipatheni eyandisa ubungakanani bangaphandle bemveliso kwaye yongeza ezinye izandiso zepatheni kwindawo yokusika. Isetyenziswe ngokukodwa kwinkqubo yokuvelisa nganye ngaphakathi kwenkqubo yokunyamezela kwayo ukuphepha imiphetho emhlophe okanye ukusika umxholo wemveliso egqityiweyo emva kokusika.

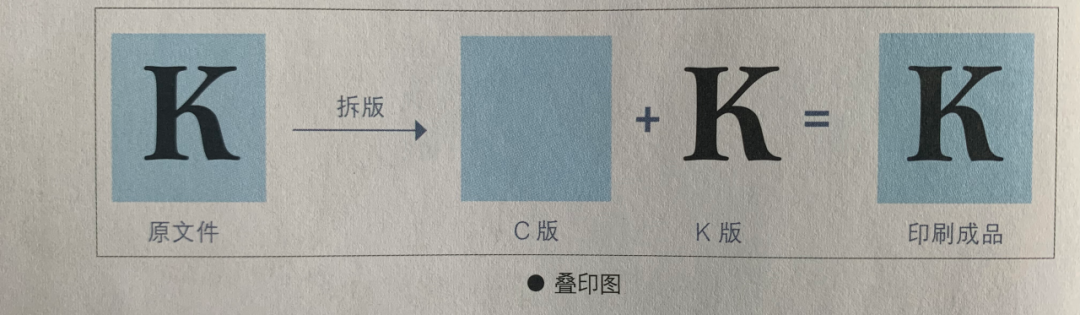

Overprinting

Ikwabizwa ngokuba yi-embossing, oko kuthetha ukuba umbala omnye uprintwa ngaphezulu komnye umbala, kwaye i-inki iya kuxutywa emva kokushicilela ngaphezulu.

Owona mbala uprintiweyo ungowodwa omnyama, kwaye eminye imibala ayishicilelwanga ngokugqithisileyo.

Overprinting

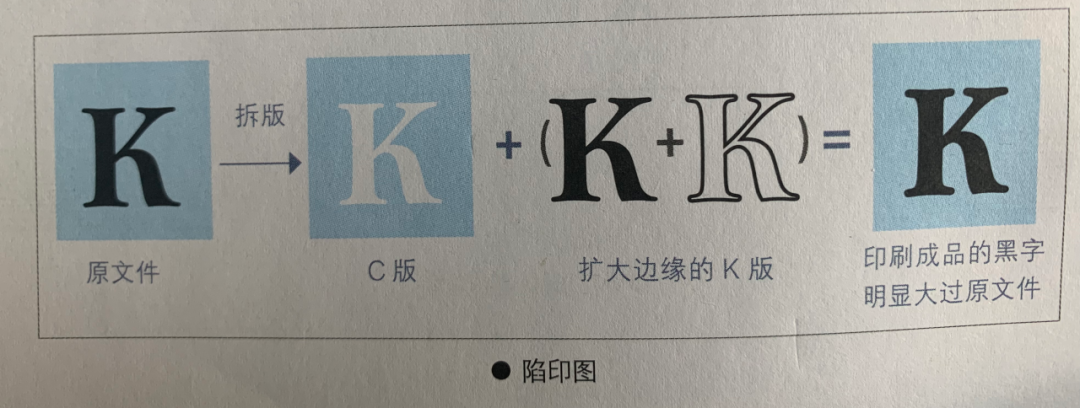

Kuphephe ukuxuba ii-inki. Ngesiqhelo xa izinto ezimbini zitshayisana, umbala oprintwe kamva ukhutshelwa ngaphandle kwi-overlap ukuze ii-inki ezingaphezulu nezisezantsi zingaxubeki.

Izinto eziluncedo: Ukuveliswa kakuhle kombala

Ukungalungi: Akunakwenzeka ukuprinta ngokuchanekileyo, kunye namabala amhlophe (umbala wephepha)

Ukubambisa luguqulelo olulungisiweyo loshicilelo olungaphezulu. Ngokwandisa umda wento enye, umbala wecala uya kudibanisa nombala wangaphambili. Ushicilelo olugqithileyo aluyi kubonisa naziphi na iziphelo ezimhlophe nokuba i-offset. Umphetho ukhuliswa ngokubanzi nge-0.1-0.2mm.

Ukumisela

Umahluko wombala

Kwenzeka njani umahluko wemibala?

Umbala weemveliso eziprintiweyo zichatshazelwa yizinto ezifana nemodi yombala, iipropati ezibonakalayo ze-substrates, iiparameters zenkqubo yomatshini, amava enkosi yokuxuba inki, ukukhanya, njl. Ezi zinto zihluke, ngoko ke ukungafani kombala kuya kwenzeka.

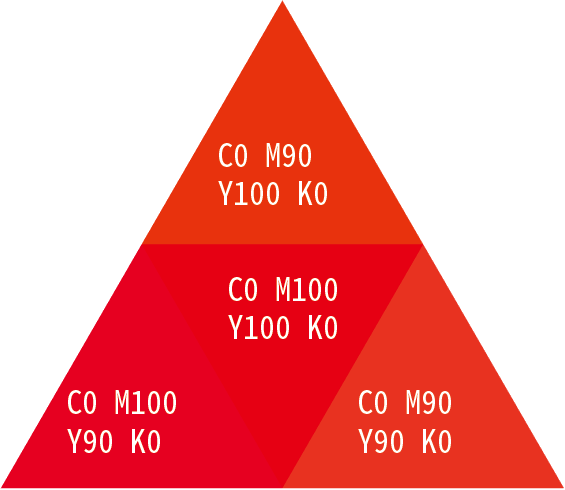

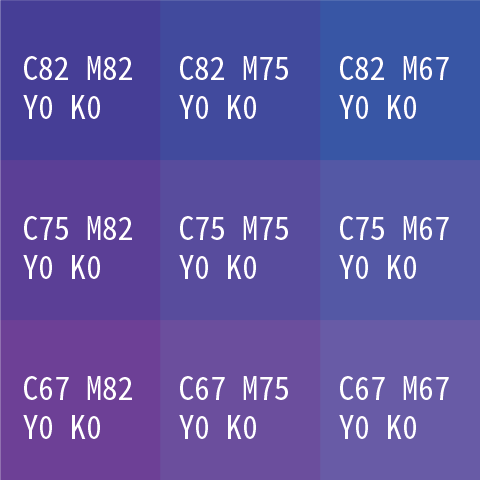

Ekushicileleni, kukho imibala emininzi ebizwa ngokuba yimibala eyingozi. Iimveliso eziprintiweyo zithandwa ukutenxa kombala, ngoko ke akukhuthazwa ukuba kusetyenziswe le mibala ekushicileleni. Kungcono ukusebenzisa imibala eqhelekileyo endaweni yoko.

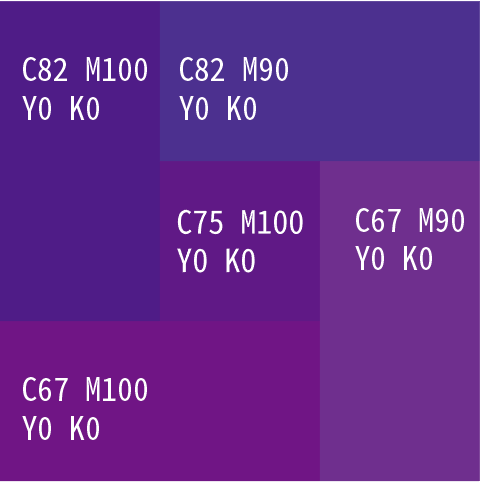

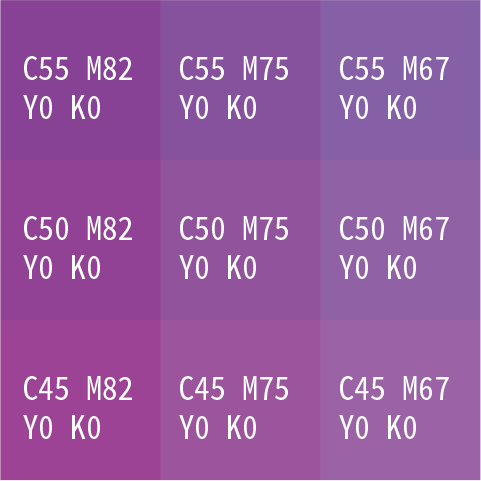

Makhe sijonge kumboniso wale "mibala iyingozi" ngaphakathi koluhlu lwemibala ye-10%:

umbala orenji

inavy Blue

Mfusa

Ntsundu

Imibala emine engwevu

Imibala emine emnyama

Umbala omnye omnyama C0M0Y0K100, kulungele kakhulu ukutshintsha ipleyiti yokushicilela, ipleyiti enye kuphela kufuneka itshintshwe.

Imibala emine emnyama i-C100 M 100 Y100 K100, akulula kakhulu ukutshintsha ipleyiti, kulula ukuba nombala owenziweyo okanye ukubhaliswa kakubi. Ngoko ke, ngokuqhelekileyo akukhuthazwa ukusebenzisa imibala emine emnyama, kwaye izityalo ezininzi zokuprinta azishicileli imibala emine emnyama.

Ixesha lokuposa: May-20-2024