Isitampu yindlela ebalulekileyo yokuhlobisa indawo yentsimbi. Nangona igolide kunye nesilivere yoshicilelo lwe-inki inefuthe elifanayo lentsimbi yokuhombisa ngeisitampu esishushu, kuseyimfuneko ukufezekisa impembelelo ebonakalayo enamandla ngokusebenzisa iisitampu esishushu inkqubo.

Ukwenziwa ngokutsha okuqhubekayo kweisitampu izixhobo kunye nezinto ezixhasayo ziye zatyebisa iifom zokubonisa zeisitampu ubuchule. Ngoku kukho iindidi ezisixhenxeisitampu ubuchule:

01: Isitampu esisicaba esiqhelekileyo

Eyona ixhaphakileyoisitampu esishushu kukushiya kungenanto macala onke ukuqaqambisa iisitampu esishushu umzimba. Xa kuthelekiswa nezinye izitampu ezishushu, inkqubo yokuvelisa ilula. Ukuba ubungakanani abukho bukhulu, ipleyiti ye-zinc ingasetyenziselwa isitampu esishushu.Umcabaisitampu kuthetha ukuba inqwelo-moya yedatum yifa elisicaba, eligximfizwe kumsebenzi osicaba iqhekeza okanye inxalenye yomsebenzi iqhekeza.

Olu hlobo lwembonakaliso lunokuthi lufakwe kwimizobo kunye nesicatshulwa, esinokuthi sibe shushu isitampu kwinqwelomoya; Isenokuba yipleyiti ye-silicone ecaba, eshushu isitampu kumfanekiso ophakanyisiweyo kunye nesicatshulwa.

02: Isitampu esichasene nomhlophe ebaleni

Ngokuchaseneyo neflethiisitampu indlela, inxalenye yomxholo ishiywe ingenanto, ngelixa indawo yangasemva iisitampu esishushu. Ubungakanani beisitampu esishushu indawo ixhomekeke kwiimfuno zoyilo lwemveliso. Ukuba iisitampu esishushu indawo inkulu, kuyimfuneko ukuqwalasela ukuba umsebenzi wayo wokubambelela uhlangabezana neemfuno zenkqubo.

03: Seta isitampu

Ngokweemfuno zomzobo, ukwenzela ukwenza isitampu kunye nokushicilela inxalenye yokudibanisa okuhlakaniphile, ukuprinta kwi-stamping kuqala. Kwinkqubo yokuvelisa, ukulungelelaniswa kuphezulu, kwaye ukulungelelaniswa kuchanekile ukufumana umphumo ogqibeleleyo.

04: Isitampu sokuphindaphinda

Ngexesha lemveliso yeisitampu ipleyiti, umfanekiso ophambili kunye nemizobo yangasemva yahlulwe ngemigca yobunzima obahlukeneyo okanye isalathiso ukwenza isiphumo sokuphinda siphinde sigxininise ingqiqo yobugcisa bemigca yegraphic. Ngokuqhelekileyo, i-laser engraving plate isetyenziswa.

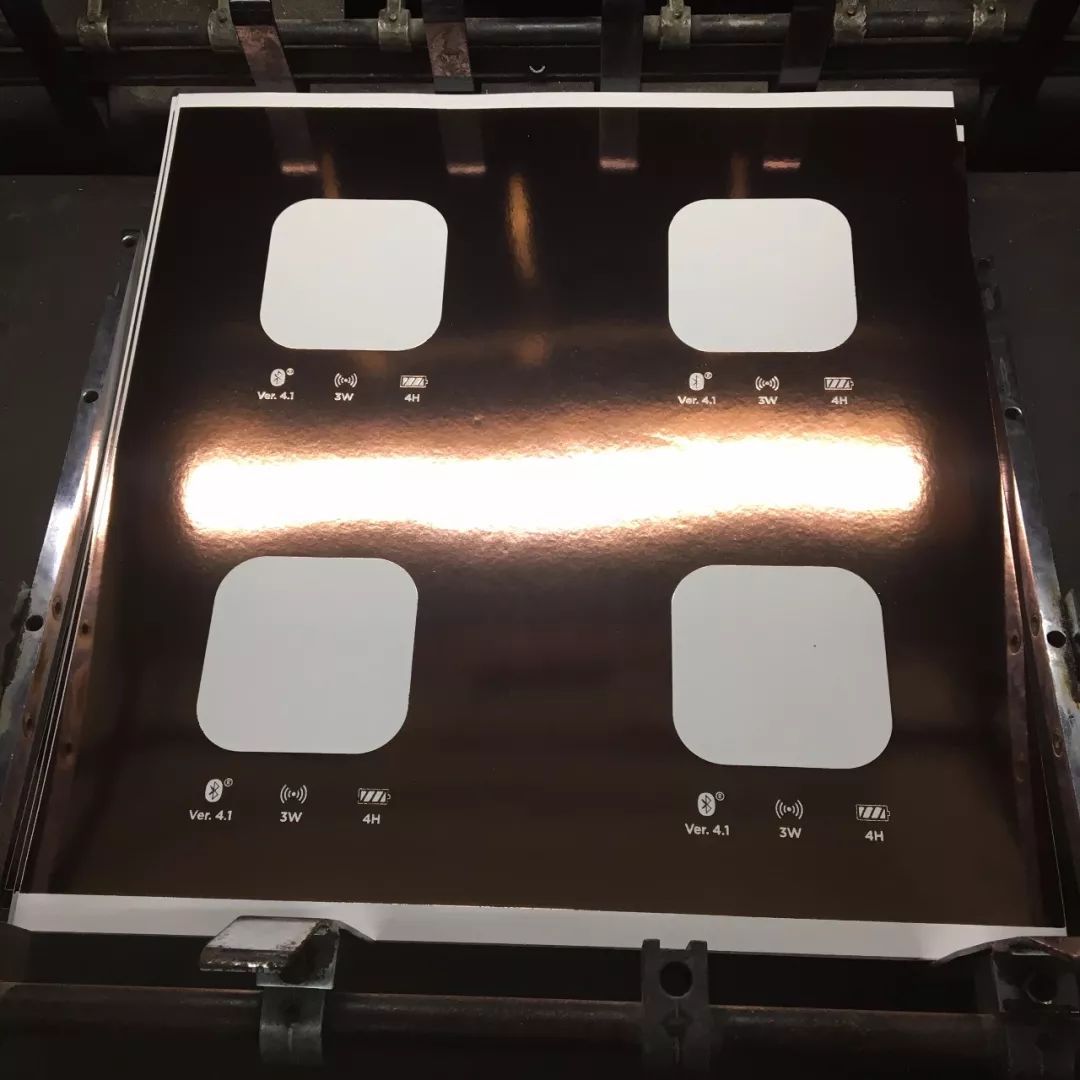

05: Izitampu ezininzi

Iphindaphindweisitampu esishushu ngaphezulu kwamaxesha amabini kwindawo yomzobo efanayo ifuna inkqubo yoqhubekeko oluninzi. Ngelo xesha, ingqalelo kufuneka ihlawulwe ukuhambelana kweefolthi ezimbini zegolide ukukhusela i-phenomenon of adhesion loose.

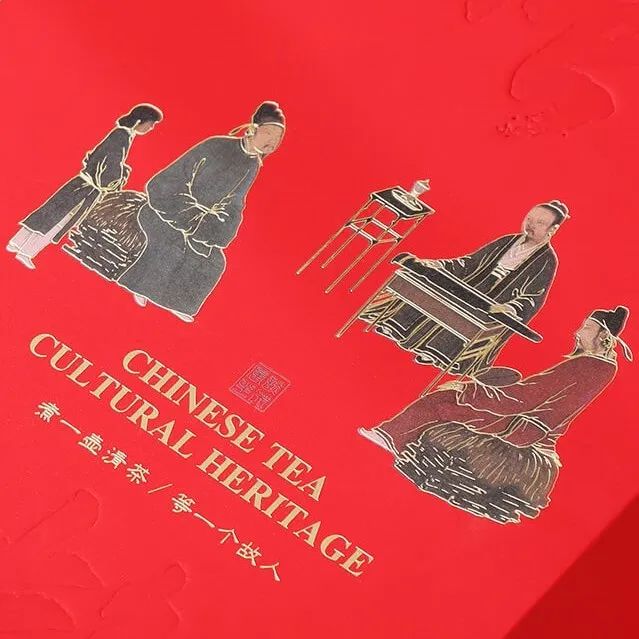

06: Isitampu esibhalwe phantsi

Kuyafana nokufaka i-embossing kunye ne-embossing, kodwa i-embossing kunye ne-embossing ihlawula ingqalelo ngakumbi kumgangatho wokwenza i-embossing kunokuba i-embossing effect. Ngokuqhelekileyo, i-embossing kunye ne-embossing plates isetyenzisiweyo, kwaye ukuphakama kwe-embossing kufuneka kube ngaphakathi koluhlu loxinzelelo lomphezulu we-foil yegolide.

Iimveliso zicutshungulwa ngokufaka i-embossingisitampu itekhnoloji ekhoyo embossed isiphumo sepateni ye-ntathu-dimensional, ngoko ke inkqubo yoshicilelo ngaphambiliisitampu yamkelwe. Ngexesha elifanayo, ngenxa yokuchaneka kwayo okuphezulu kunye neemfuno eziphezulu, kukulungele ngakumbi ukusebenzisashushuiteknoloji yesitampu.

Njengoko unokucinga, abaqulunqi kufuneka baqwalasele ngokucophelela ukuthungwa, ubunzima, i-foil yegolide kunyeushicileloi-inki xa ukhetha iphepha okanye ezinye izinto zokuthwala inkqubo ye-three-dimensional stamping. Ukulungelelaniswa kwamacala angaphambili nangasemva nako kubalulekile.

Ngexesha elifanayo, ubukhulu bephepha buya kunciphisa umgangatho kunye nomphumo wemveliso egqityiweyo ngexesha lokusebenza. Umzekelo, iphepha elibhityileyo kakhulu okanye elinokuqina okulambathayo liya kubangela ukugqabhuka kwephepha.

07: Isiphumo esikhethekileyo sokucofa isitampu

Ngokweemfuno zokuyila, iphethini yempembelelo ekhethekileyoisitampu yenziwe ukugqamisa iziphumo ezahlukeneyo zendlela eyodwa.

Kusetyenziso olusebenzayo lweisitampu esishushu inkqubo, ukhetho metalisitampu ipleyiti,isitampu esishushu iphepha, iphepha kunyeisitampu intetho ichaphazela ngqo okokugqibelaisitampu isiphumo.

Isitampu ngoku sisetyenziswa ngokubanzi kwiindawo ezahlukeneyo zokuprinta nokupakisha. Ikwayitekhnoloji yokushicilela kuphela enokuvelisa iziphumo zentsimbi eziqaqambileyo, ezingaguquguqukiyo kwiphepha, iplastiki, ikhadibhodi kunye nezinye iindawo zokushicilela.

Ixesha lokuposa: Feb-07-2023